i had the great idea of trying to put a titanium cylinder into a 327 night guard and was able to order one from smith. When i got it, there was a lot of excess material left on the extractor. Did they forget a step? i find it hard to believe that they have to hand fit every extractor......

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

machining extractor star

- Thread starter feal

- Start date

Register to hide this ad

Protocall_Design

Vendor

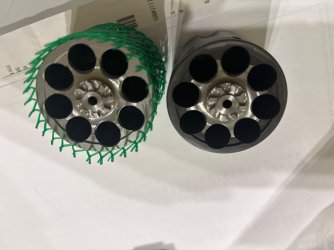

It looks like the old one was made with a circular shape on the extractor tips, where the new ones have a square profile. Normally, the older circle shape had 2 index pins to keep it in place, where the new kind has no pins and uses the square shape to keep it in place.

- Joined

- Jul 26, 2004

- Messages

- 497

- Reaction score

- 598

When I fit a brand new .32 magnum cylinder it came with raw ratchets on the extractor. I had to file each one with a barrette file to have it carry up correctly. This takes quite a bit of time to do it right.

I recommend consulting Kuhnhausen's book on revolvers for the details.

Are the extractors interchangeable from one cylinder to the next? If so, that might work for you.

I recommend consulting Kuhnhausen's book on revolvers for the details.

Are the extractors interchangeable from one cylinder to the next? If so, that might work for you.

Last edited:

Protocall_Design

Vendor

If I'm understanding, are you saying that the extractor fits in the cylinder, but the trigger can't be pulled all the way back when the cylinder is closed?

If that's the case, you just need a thinner hand to slide past the ratchet. With the sideplate off, you can look in the back of the hand window and watch the interaction of the hand to the ratchet. In normal operation, the hand turns the cylinder until it locks into position, then slides on up past the ratchet. The hand has to be wide enough to lock the cylinder, but thin enough to go on past. There is a fine line between too wide and too thin.

If that's the case, you just need a thinner hand to slide past the ratchet. With the sideplate off, you can look in the back of the hand window and watch the interaction of the hand to the ratchet. In normal operation, the hand turns the cylinder until it locks into position, then slides on up past the ratchet. The hand has to be wide enough to lock the cylinder, but thin enough to go on past. There is a fine line between too wide and too thin.

I was told the extractors were match drilled to the cylinder- it could be possible to swap, but the black one is a different thickness because it doesn't take moon clips.

Does the factory have to file each ratchet to fit?

Thanks for all the replies- I'll probably go play around with it some more this weekend

Does the factory have to file each ratchet to fit?

Thanks for all the replies- I'll probably go play around with it some more this weekend

Protocall_Design

Vendor

The factory machines each ratchet the same and fits the hand to the ratchets. Lately, they have not been fitting the hand, and using hands that are too wide.

Lou_the_welder

Member

I put a titanium cylinder on my R8. The way I did it was i unscrewed the original extractor from the old steel cylinder. It worked! No way was i going to time 8 ratchets correctly.

Anywho, I shot it a couple times. With shorts , it worked fine. No shaving- cylinder stopped perfectly. Even checked the chambers. They were good.

Then , I shot some 357 158gr ( aka: nukes) thru the titanium cylinder. I got sparks to fly( sideways) and I could visibly see them too. I even took video. I experienced titanium erosion. My nukes were enough to send flame at least 10" from the sides and that cylinder didn't like it.

and I could visibly see them too. I even took video. I experienced titanium erosion. My nukes were enough to send flame at least 10" from the sides and that cylinder didn't like it.

So, off it went. Put the steel cylinder back on.

I liked having all the advantages a titanium cylinder gives. In my experience, having the bullets too close to the edge will erode the cylinder over time. At least with the powder I was using. W231.

Anywho, I shot it a couple times. With shorts , it worked fine. No shaving- cylinder stopped perfectly. Even checked the chambers. They were good.

Then , I shot some 357 158gr ( aka: nukes) thru the titanium cylinder. I got sparks to fly( sideways)

and I could visibly see them too. I even took video. I experienced titanium erosion. My nukes were enough to send flame at least 10" from the sides and that cylinder didn't like it.

and I could visibly see them too. I even took video. I experienced titanium erosion. My nukes were enough to send flame at least 10" from the sides and that cylinder didn't like it.So, off it went. Put the steel cylinder back on.

I liked having all the advantages a titanium cylinder gives. In my experience, having the bullets too close to the edge will erode the cylinder over time. At least with the powder I was using. W231.

Green Frog

Member

My one experience with the later style extractor was when I had a later 617 cylinder reamed to 327 Fed Mag. My gunsmith told me it was extra work for him and charged accordingly. Now when I look for 22 cylinders to convert, I look for the older style.

Similar threads

- Replies

- 2

- Views

- 556

- Replies

- 10

- Views

- 1K