I have to disagree with a lot you say here.

"What you say about the model is almost correct. After 1950 this model became known as the Model 1950 .44 Military. When it was manufactured, ca. 1916, this designation did not exist."

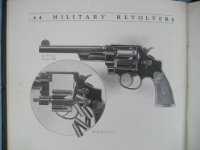

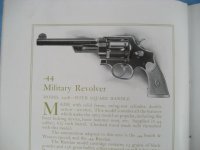

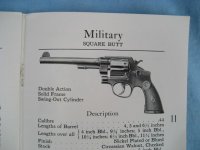

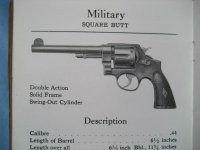

Actually, S&W catalogged the 44's as the "44 Military" from day one, starting with the Triple Lock in the 07-08 catalog and continuing thru all or most catalogs.

Lee, I'll give you this, but to my recollection it wasn't too commonly used, and I don't recall McHenry & Roper using the term.

_____________________

"The flat plug in the butt is another indication of factory work as this would have been either a lanyard loop or a domed plug. If a loop it would have been removed, if the domed plug these were polished flat as they are in a blind hole, tight, and cannot be removed once installed."

The only positively plugged swivel holes I am aware of is on post WW II 38 M&P (Victory) frames. It MAY have been done on one or two 1917's heavily modified- like with target sights.

You're going to have to revise your thinking on this. I have seen several, and owned one, SN 21159, that had the domed solid plug. It was a 5". I recall a second 5" specifically with the solid plug that I wish I had bought. I have seen one or two more at shows over the years, but it has been quite a while.

_________________________

"Other indications of a factory re-finish are the still color case-hardened and not plated hammer and trigger, as well as the blue extractor."

I've seen a lot of after-market jobs that did not plate the parts that shouldn't be.

True, but until fairly recent times and competent shops like Ford's this wasn't too common except factory work.

______________________________

"Originally S&W guns are polished after all stamps and roll marks are applied."

That is fairly safe to safe for pre-war guns, but not seldom true from the WW II production onward. Look at the raised logos on Transition guns.

We were speaking of a specific time period, and the comment is accurate for the time period being discussed.

___________________________

"The frame is a left-over Model 1917 frame manufactured in ca. 1916 based on the serial number."

I agree that is a leftover 1917 frame, but no 1917 frames existed before 1917.

So, the gun is not from 1916. I have a 1916 44-2nd Model- one of the earliest made, and it is in the 14,600 range. There are Triple Locks with higher numbers. Not many 44-2nds got out before 1919-1920. The factory was buried by war production from Aug, 1914 Thru Sept, 1916 (455's). The Second Model was first produced in Jan, 1915, but the British 455's occupied most factory production till late 1916. Then, they began looking at 1917 production, and by late 1917, they were totally focused on 1917 production. The Gov't thought they were still too slow, and seized the factory in Sept, 1918. They did not return control till Jan, 1919, and it seems S&W was very slow in 1919 about getting back to civilian production.

The point of all this is to say that you won't see many N frames that were produced from later 1914 thru much of 1919 EXCEPT for 455's and 1917's.

I believe the OP's gun will have a ship date of 1920 or possibly 1919.

True to a point. Since the Model 1917 is nothing more than a slightly modified .455 MK II, as were the 2nd Model .44 HE this is a matter of semantics. So far as ship date, this will be a moot point until Roy returns a letter. That notwithstanding, the serial number in the 16,000 range, per the list in SCSW, can fall anywhere from 1916-1920.

_________________________

After WW I, the factory built many 44-2nd's on leftover 1917 frames. If you think about it, there was nothing else to build. The 455 contracts were long since done, and the 1917 contracts were done. Before the war nothing but 44 Sp's had been built in any quantity. After the war, they added the 1917 to the catalog, but they were lousy sellers, probably because SURPLUS 1917's were available- CHEAP.

So, we have noted for years that most 44-2nd's from the 20's have a butt swivel, and often show an eagle head in the yoke cut. I have never seen a 44-2nd with what I thought was a factory plugged swivel hole- they had PLENTY of leftover swivels to plug them with!

Swivel hole plug, see above.

This gun has been gone for ca. 30 years and I never had pictures of it. I can't say for sure about the Eagle in the Yoke cut, but it did have the Eagle over S** just like the military guns, stamped on the barrel flat, and my recollection is it also had this stamp on the frame at the top of the left recoil shield. Won't swear to this though.

What I can say for sure is I have a commercial 1917 from the mid-1930s, around the time of the Brazilian contract. This gun has the Eagle/S34 stamp on the barrel flat. My impression for many years was that the Eagle stamp was a military inspection stamp. I can accept, with difficulty, that a 1935 or so 1917 had a surplus barrel from the WW I contracts, but how can it be explained that it was also on a 2nd Model .44 HE barrel? Does the Eagle have another meaning to S&W not related to the military contracts?

Swivel hole plug, see above.

This gun has been gone for ca. 30 years and I never had pictures of it. I can't say for sure about the Eagle in the Yoke cut, but it did have the Eagle over S** just like the military guns, stamped on the barrel flat, and my recollection is it also had this stamp on the frame at the top of the left recoil shield. Won't swear to this though.

What I can say for sure is I have a commercial 1917 from the mid-1930s, around the time of the Brazilian contract. This gun has the Eagle/S34 stamp on the barrel flat. My impression for many years was that the Eagle stamp was a military inspection stamp. I can accept, with difficulty, that a 1935 or so 1917 had a surplus barrel from the WW I contracts, but how can it be explained that it was also on a 2nd Model .44 HE barrel? Does the Eagle have another meaning to S&W not related to the military contracts?