gwpercle

Member

The "wax" ring below the crimp groove is conventional bullet lube . The old school stuff still works for me . You do not need to add any additional lube ...unless you experience barrel leading ... but for now use them as lubed with wax .Thanks, the last few posts are really great.

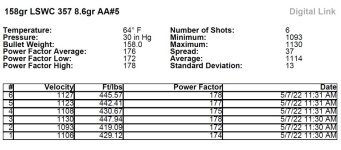

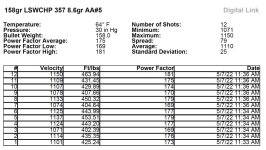

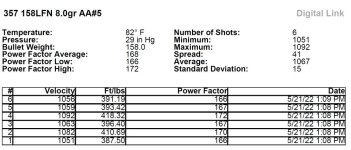

I have 12 each of both SWC and SWCHP all loaded up and will be testing tomorrow. 8.62grains AA#5

A couple of you mentioned lube. I have not read up on that yet. Sorry if its a newb question but where does the lube go? I see most of my bullet types have a ring of "wax" just below the crimp groove. I assume that is to help seal the bullet in the case? Should I be putting more lube on the base of the bullet before pressing in?

Edit: I watched some bullet lube videos on Youtube. Seems my commercial bullets are already lubed (that colored ring of wax). Do I need to add more lube that what they come with?

Coated or Powder Coated is the new school lube , it takes the place of "wax" lube and is supposed to cure all ill's , heal the sick and raise the dead and cook supper for you (I'm only joking ) ... but coated bullets are a good option .

Commerical usually come lubricated or coated and sized .

For use in 38 Special / 357 magnum .358" is the standard size and is satisfactory 99% of the time .

If you slug your barrel ...take that dimension and add .001" or some go .002" over bore diameter . I'm a .001" guy ...

I've used both .357" and .358" size in a S&W model 64 and a Ruger Blackhawk and do not see any difference in accuracy or leading in my two revolvers .

Gary

Last edited: