Figure I'll throw out my 2c.

One of the first things I learned in regards to finish work of any sorts on high polish blue, and ESPECIALLY nickel guns, is that you want a SURGICALLY CLEAN rag and work space. Do not go wiping your gun nickel down with a dusty rag. You are asking for swirl marks!

Blow your work environment off with an air compressor if you can and or work in a very clean area. Be careful about where you set your rag, avoid pet hair, dust, etc. A thorough job is going to take some time. If you have nickel flaking, or any signs of adhesion issues, I would think twice about polishing it altogether. If it's much deeper than a swirl mark, it isn't going to come out. Not saying it won't help, but don't go in with the expectations of being able to remove scratches.

Use a SOFT rag. I buy high end, heavy microfibers off of Amazon. 500 GSM or something. A thin cheap microfiber will not do! Your satin blued guns do not care, but trust me, your nickel guns do! Might cost you $20 bucks for a four pack of good ones, but spending $5 a rag beats swirl marking the piss out of your gun. I have pretty much transitioned to using these rags for everything in regards to high polish finishes, and I store them in labeled gallon zip lock bags. I have a polish rag, a wax rag, a clp rag, and a dry wipe down rag. Once they start looking used, they go into circulation with all my other rags for general cleaning on non hi gloss guns.

Work in small areas at a time. It is not a fast process. Do not be afraid to use a lot of compound. If you don't have wet compound where you're polishing, you're spinning your tires. Do one area, wipe off, and start again right next to it. Don't be afraid to overlap a little bit. Repeat.

I like using wenol. It seems less abrasive to me than flitz, and flitz isn't very abrasive. If you've followed the steps above, you can apply a fair amount of pressure if you have a super mild compound. Keep the power tools away! No dremel, no buffing wheel! Patience is your friend. If you have full thickness factory nickel with no adhesion issues, it is highly unlikely that you're going to work your way through the finish with a compound as mild as wenol. I don't have experience with the polishes you list. I would just proceed with caution and make sure they aren't aggressive enough to leave swirl marks.

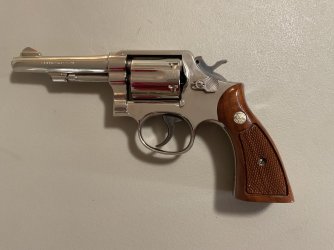

Here is a 29-2 that I cleaned up. It spent it's previous life in a presentation case that must have retained some moisture. The flocking on the case disintegrated like they all do, leaving a speckled nickel finish behind. Unfortunate because the gun appears unfired or nearly unfired as it hardly had a turn line. I got most of the freckling out, but again, don't expect to polish out anything deeper than a swirl mark. Note that the before photos suck. The brass color in the before photos is glare and oil. If you see gold like that that isn't oil or glare, the nickel plating is gone in that area. Same gun, two different sets of grips in the after photos.