Yeah, this is an oddball round I'm loading. Its not in any books, its a pretty unique bullet. I've seen references to people doing all kinds of strange things in 45 acp cases and I don't think this is way 'out there'.

I'm still convinced 4.2 grains of bullseye is pretty light and that the max would be at least 4.8 for this weight bullet. The effect of case capacity is the big unknown, but since I believe I'm well under max 45 ACP (21,000 PSI), and this gun can easily handle .45 ACP +P (23,000 PSI), .45 Super (28,000 PSI), and even .460 Rowland (40,000 PSI) its hard to imagine that I'm anywhere near a dangerous load.

The closest data I could find is all for round nose,

hdy 230 LRN BE 4.5-5.7

lee 230 Lead BE 3.6 (auto rim)

lee 230 FMJ BE 4.5 (auto rim)

lee 230 FMJ BE 5.0

lee 230 Lead BE 4.0

lee 240 FMJ BE 4.9-5.0

lee 260 FMJ BE 4.3-4.5

lyman 225 LRN BE 4.0-5.0

lyman 225 LRN BE 3.0-4.5 (auto rim)

-----

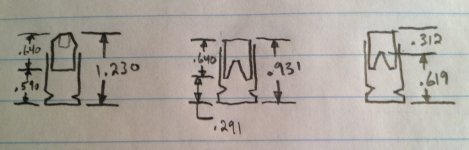

My favorite load so far is a Ranier plated 200 grain SWC over 5.6 grains of bullseye at 1.235-1.240 OAL. That should be good for right around 900fps and is comfortably below max according to Hornady (max 6.3) and Lyman (max 6.0). I can put 30 of them thru a ragged hole barely over 2" center to center at 10 yards, which is well beyond my normal shooting abilities.

I've fired the Buffalo Bore 32A load, a 255 grain hardcast flat point in auto rim at 1030 fps (according to BB) from my 4" tube. That sucker is hot, hotter than factory 45 colt with the same bullet.

I'm headed to the range this evening to find out how much bang I get and how accurate the HBWC's are.

Everything you posted here is totally irrelevant!

You have changed the case capacity so all the posted load data you have above is meaningless.

How do you know what the pressure is?? You are just rationalizing your decision.

Why post if you are going to do what you want anyway??