ditto on what has been said about RP brass and crimp.

My biggest source of problems with bullet setback has been with RP brass. It is very thin and doesn't have sufficient neck tension. .452 lead bullets setback less than .451 jacketed but is still a problem. My RP brass has been relegated to my 625.

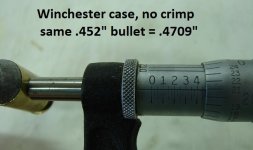

Increasing crimp doesn't increase neck tension, it decreases it and makes the problem worse. It is best to apply just enough to remove the case flare, so that it feeds reliability.

I am skeptical of the 'heavy rollcrimp' advice for magnum revolver cartridges. I've compared posted pictures with factory loaded .357 cartridges. A lot of the pictures show crimp far heavier than any factory load I've used, and none of the bullets have every jumped the crimp.

Neck tension is important for revolver cartridges too.

BTW, I taper crimp my 625 ammo also, never had a bullet pull out of a case even with RP brass.

My biggest source of problems with bullet setback has been with RP brass. It is very thin and doesn't have sufficient neck tension. .452 lead bullets setback less than .451 jacketed but is still a problem. My RP brass has been relegated to my 625.

Increasing crimp doesn't increase neck tension, it decreases it and makes the problem worse. It is best to apply just enough to remove the case flare, so that it feeds reliability.

I am skeptical of the 'heavy rollcrimp' advice for magnum revolver cartridges. I've compared posted pictures with factory loaded .357 cartridges. A lot of the pictures show crimp far heavier than any factory load I've used, and none of the bullets have every jumped the crimp.

Neck tension is important for revolver cartridges too.

BTW, I taper crimp my 625 ammo also, never had a bullet pull out of a case even with RP brass.