As suggested I'd try acetone and instead of a torx bit a good screwdriver. I know it seems like the same as a bit but it's not. Even if you had to get a small set or single from a snap on truck it would help.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Screw Removal Problem

- Thread starter Rick H.

- Start date

One additional thought. Try applying your heat as you did previously then apply your Kroil. As the screw/threads naturally cool, the Kroil will be drawn down into the junction. It has worked for me on larger parts.

I'd try this and then follow it up by putting the gun in a padded vise, put the torx bit in a holder and lock onto the bit holder with a set of vice grip pliers.

Apply a moderate amount of torque to the screw with the vice grips & torx bit assembly, and then tap the end of the bit holder with a small hammer. Basically using it like an impact-driver.

I've "jarred" more than one stuck screw loose with this type of technique.

- Joined

- Oct 17, 2006

- Messages

- 7,781

- Reaction score

- 7,196

Choose wisely...blue Locktite is YOUR friend, red Locktite is the friend of the assembly!

Used in large amounts on properly prepped material, blue loc-tite can be really, really close to red.

BTW, color isn't necessarily a true indicator of properties. The loc-tite product number is.

Heat for loctite, all good suggestions have been mentioned. I have one point that is results of a working career as an electrical and instrument mechanic, buy quality tools and quality tools are not cheap and pistols and optical sights are not cheap, soooo.

Jeppo

Member

I'd try this and then follow it up by putting the gun in a padded vise, put the torx bit in a holder and lock onto the bit holder with a set of vice grip pliers.

Apply a moderate amount of torque to the screw with the vice grips & torx bit assembly, and then tap the end of the bit holder with a small hammer. Basically using it like an impact-driver.

I've "jarred" more than one stuck screw loose with this type of technique.

I had a faucet cartridge that had welded itself into the faucet. No amount of torque resulted in anything more than rounding off the flats. I asked a retired machinist friend to try to save it for me with the only alternative being replacing both matching faucets in the bathroom.

A couple days later, he handed the two parts back to me and said he used this exact technique of lightly tapping as he turned.

Used in large amounts on properly prepped material, blue loc-tite can be really, really close to red.

BTW, color isn't necessarily a true indicator of properties. The loc-tite product number is.

I can't say I really agree with these statements.

In my experience, blue loc-tite never really gets fully hard. It stays kind of "gummy" - but red loc-tite fully hardens. Comparing the two is kind of like comparing a flexible silicon adhesive to super glue.

I guess if you slather enough blue loc-tite on a fastener you can make it about as hard to remove as one that had the appropriate small amount of red loc-tite applied to it. But if you use both appropriately the difference in how hard the screw will be to remove is very significant. Blue is for securing a fastener from backing out due to vibration, red is for permanently securing a fastener.

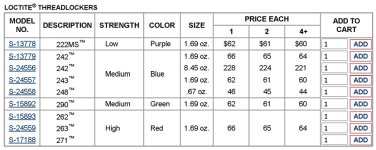

As for color vs product number, a quick look at their website shows that there are 4 different strength ranges that correspond to colors.

These different color "families" designate the product's relative bond strength - purple is a low-strength bond (1 product number), blue (3 product numbers) and green (1 product number) are medium bond strength, and red (3 product numbers) are high bonding strength.

The different products - with individual product numbers - within the color-range families are similar to each other, just slightly different in their relative bond strength and viscosity - for slightly different specific applications.

So, color does indicate relative strength, but there are different levels of bonding strength, viscosity, and application within a couple of the different color families.

See the chart below.

Attachments

Last edited:

Rick:

There are several different smaller impact tools that would probably work very well for removing the torx head screw. That would be my first choice for your dilemma. Check on line. Endevor to persevere.

There are several different smaller impact tools that would probably work very well for removing the torx head screw. That would be my first choice for your dilemma. Check on line. Endevor to persevere.

Last edited:

OP

Quick update, I took the slide into a gunsmith and asked him if he could remove the screws and he thought he could. He latched onto one of his best Torx drivers if proper size and gave the first screw a good hard twist. I was shocked when it came out after a good loud snap sound. He wasn't so lucky on the second screw and his Torx bit snapped in two. I had to leave the slide with him so he could come up with a plan "B" for getting the screw out. I looked at the screw he got out and there was no paint on it anywhere so obvisously the Kroil took care of the paint. The screw had a blue locking agent on it and it also had a whitish looking substance on it that looked like dried Rocksette. So at least at the outset these screws may have had 3 substances on them, an oil based paint, a blue thread locker buried in the screw threads and quite possibly Rocksette. All of this is a recipe for disaster, but it did hold the optic on that's for sure. I will be interested on how the gunsmith I took the slide to removes the last screw. More to follow at some point.

Thanks again for all the replies.

Rick H.

Thanks again for all the replies.

Rick H.

Thank you for the update.

OP

Last update on this situation. I was shocked when I received a notice the day after I took my slide and optic into the gunsmith for repair that it was ready for pickup. Not one full working day and it was finished! Unbelievable!! I went to pick it up and was charged the lowly amount of $45.00 for the screw removal, cleanup and reinstallation of the optic with a new battery in it. I guess our wires got crossed up because I really didn't want them to install the optic as I wanted to do that myself, but what the heck, it was installed. The slide and optic looked in excellent condition without damage

I asked if I could talk to the gunsmith that did the repair and he came out from the shop and I asked him if he didn't mind, could he tell me how he got the stuck screw out. He smiled a bit and said sure and then proceeded to tell me how he did it. His method for this was pretty simple. He put the slide in a padded vise and took a straight punch that went to the bottom of the screw through the Torx head opening and gave it a few good hits. Not enough to damage the screw or threads just dislodge it if possible. At that point he told me he told me there are good Torx drivers and cheap Torx drivers. Good ones fit tight in the screw head and can withstand substantial rotational force while cheap ones just break. Good bits are expensive at around $5.00 or more dollars apiece. I have since perused the internet and found what I think are some better Torx bits and ordered them for the next job I have.

I didn't get a chance to see the second screw that was removed from the slide, but clearly the paint had little affect on the first screw as the Kroil had removed it all. Unfortunately the Kroil had little to no affect on the thread locker, which actually looks like two types of thread lockers. I pretty much go by what manufacturers say about screw tightness, but I think in the future I will lighten up a bit on small screw torque and keep an eye on the screws at first, especially if the Torx screw uses a #8 bit or less. If I decide to mark screws for any potential loosening I will scribe a line on them. No paint for me although I did not mark the problem screws. All in all this was a good learning experience for me. Clearly Torx screws can take a lot more force than I thought they could as long as you use good drivers. Good tools equal better results.

Rick H.

I asked if I could talk to the gunsmith that did the repair and he came out from the shop and I asked him if he didn't mind, could he tell me how he got the stuck screw out. He smiled a bit and said sure and then proceeded to tell me how he did it. His method for this was pretty simple. He put the slide in a padded vise and took a straight punch that went to the bottom of the screw through the Torx head opening and gave it a few good hits. Not enough to damage the screw or threads just dislodge it if possible. At that point he told me he told me there are good Torx drivers and cheap Torx drivers. Good ones fit tight in the screw head and can withstand substantial rotational force while cheap ones just break. Good bits are expensive at around $5.00 or more dollars apiece. I have since perused the internet and found what I think are some better Torx bits and ordered them for the next job I have.

I didn't get a chance to see the second screw that was removed from the slide, but clearly the paint had little affect on the first screw as the Kroil had removed it all. Unfortunately the Kroil had little to no affect on the thread locker, which actually looks like two types of thread lockers. I pretty much go by what manufacturers say about screw tightness, but I think in the future I will lighten up a bit on small screw torque and keep an eye on the screws at first, especially if the Torx screw uses a #8 bit or less. If I decide to mark screws for any potential loosening I will scribe a line on them. No paint for me although I did not mark the problem screws. All in all this was a good learning experience for me. Clearly Torx screws can take a lot more force than I thought they could as long as you use good drivers. Good tools equal better results.

Rick H.

Tinkertech

Member

- Joined

- Nov 2, 2024

- Messages

- 56

- Reaction score

- 78

I once had a Benille Nova 12 Ga shot gun that had a damage magazine tube that needed to be replaced.

No big deal I thought, it just screws in. Much to my surprise the tube would not budge no matter what I did, I tried all the tricks.

I finally contacted Loctite and they surmised that the tube had been installed with RED Loctite, you could see small traces of it. To make matters worse the tube had extremely fine threads.

According to Loctite the only way to break loose RED Loctite was to heat the parts to 350* because no solvent would work.

So I heated up the magazine tube with a propane touch and using a strap wrench finally got it off.

RED Loctite is the devil and should never be used on anything that would ever have to be unassembled.

No big deal I thought, it just screws in. Much to my surprise the tube would not budge no matter what I did, I tried all the tricks.

I finally contacted Loctite and they surmised that the tube had been installed with RED Loctite, you could see small traces of it. To make matters worse the tube had extremely fine threads.

According to Loctite the only way to break loose RED Loctite was to heat the parts to 350* because no solvent would work.

So I heated up the magazine tube with a propane touch and using a strap wrench finally got it off.

RED Loctite is the devil and should never be used on anything that would ever have to be unassembled.

OP

Last point on this matter....I am not an engineer, nor a gunsmith or even a machinist. Just a regular guy interested in working on firearms. I don't consider myself a "bubba" by a long shot and like to do my own work whenever possible as I don't trust others in many cases to do the work correctly and without damage. I have never liked a # 6 screw with a #8 Torx head on them. It always seemed to me to be a very small head on a screw that can be subjected to a great deal of force. Add in a threadlocker of unknown make and it compounds the problem.

To make matters worse we have at our disposal many makes of unknown quality Torx bit drivers including Torx Plus and Torx security drivers. Which of these to use and when best to use them? What is the strongest for a given application? No one seems to really know and if they do they aren't saying? What is the maximum load that one can put on a Torx driver before it twists or breaks? A trip to my hardware store revealed at least four different makes of Torx bit drivers in #8 size, but no one there seemed to know what was the strongest one.

Looking up information on the internet on these screws and drivers was quite revealing. Torque loads on these screws and bits was all over the place. Some were really quite low, much lower than what I thought. For some reason I thought 15 inch pounds was a good torque limit on these screws, but from what I read both in the USA and across the pond that information may not be correct. Of course one has to remember the quality of the screws and drivers must be taken into consideration. So after becoming somewhat confused by all this I am going to reconsider what I feel is a "safe" torque limit on these screws. I could be wrong, but I think 10 to 12 inch pounds is the limit. 10 if I am applying threadloacker. I always use an inch pounds torque driver when tightening these screws. Even at a 10 inch pound limit I see some twisting of the cheaper Torx bit drivers from the hardware store.

So it really comes down to what do you feel comfortable with in tightening or loosening these small screws? I hate dealing with stripped or broken small screws, so for now anyway less may be better. Anyone care to add to this?

Rick H.

To make matters worse we have at our disposal many makes of unknown quality Torx bit drivers including Torx Plus and Torx security drivers. Which of these to use and when best to use them? What is the strongest for a given application? No one seems to really know and if they do they aren't saying? What is the maximum load that one can put on a Torx driver before it twists or breaks? A trip to my hardware store revealed at least four different makes of Torx bit drivers in #8 size, but no one there seemed to know what was the strongest one.

Looking up information on the internet on these screws and drivers was quite revealing. Torque loads on these screws and bits was all over the place. Some were really quite low, much lower than what I thought. For some reason I thought 15 inch pounds was a good torque limit on these screws, but from what I read both in the USA and across the pond that information may not be correct. Of course one has to remember the quality of the screws and drivers must be taken into consideration. So after becoming somewhat confused by all this I am going to reconsider what I feel is a "safe" torque limit on these screws. I could be wrong, but I think 10 to 12 inch pounds is the limit. 10 if I am applying threadloacker. I always use an inch pounds torque driver when tightening these screws. Even at a 10 inch pound limit I see some twisting of the cheaper Torx bit drivers from the hardware store.

So it really comes down to what do you feel comfortable with in tightening or loosening these small screws? I hate dealing with stripped or broken small screws, so for now anyway less may be better. Anyone care to add to this?

Rick H.

- Joined

- Oct 17, 2006

- Messages

- 7,781

- Reaction score

- 7,196

Read your posts 31 & 33. First, not all bolts/screws (or the drivers) are created equal. When I went shopping for screws for RDOs, McMaster-Carr listed high strength alloy screws of the correct size. They're described/labeled as Torx Plus and the pack includes 2 drivers that fit 1/4 in hex. I invested in the torque limited driver they sell for that screw size, but as I noted earlier, I'm a wee bit chicken to take it to the limit. Occasionally checking for loose screws seems better than thread lockers in this particular use.

I read the description of Torx Plus and it seems a stronger system than the original Torx. But, they don't mention why except that it appears the indent in the head allows for stronger splines on the drivers. They did mention that conventional Torx bits will work on the Plus screws.

This is one of those cases where access to an optical comparitor would be nice to be able to actually see the differences. You can see a lot at 3200X.

I read the description of Torx Plus and it seems a stronger system than the original Torx. But, they don't mention why except that it appears the indent in the head allows for stronger splines on the drivers. They did mention that conventional Torx bits will work on the Plus screws.

This is one of those cases where access to an optical comparitor would be nice to be able to actually see the differences. You can see a lot at 3200X.

Last edited:

IMO, even 10 inch-pounds might be too much for most applications.

If you use a little dab of blue loc-tite to prevent the screw from loosening on its own you don't need nearly as much torque to keep the screws tight.

If you use a little dab of blue loc-tite to prevent the screw from loosening on its own you don't need nearly as much torque to keep the screws tight.

Similar threads

- Replies

- 38

- Views

- 2K

- Replies

- 13

- Views

- 709

- Replies

- 9

- Views

- 951

- Replies

- 10

- Views

- 436