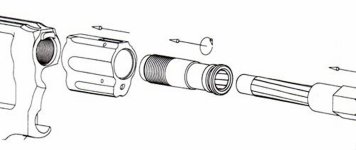

Anyone have any tips or tricks on how to remove the two piece barrel from a S&W? I’m ‘trying’ to remove the barrel from a 2.75# (sic) Model 66-8 but accept for diameter/caliber they should be the same.

Oh, how about getting the brass rod out that snapped off flush with the muzzle...

Oh, how about getting the brass rod out that snapped off flush with the muzzle...