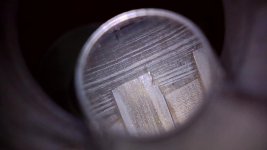

I have a new 686-6 with a defective forcing cone. Referring to the digital bore scope image, significant burrs have been pulled off the side of each rifling land and laid over into the adjacent groove. This image is of the replacement barrel following return from Smith & Wesson. The first barrel showed equivalent defects. I also owned a recent model 986 with very similar forcing cone defects. Apparently, this is becoming a common quality defect in Smith & Wesson revolvers.

Burrs at these locations are certain to cut grooves down the full length of the bullet bearing surface creating significant leak paths for high pressure gas. These leaks will reduce velocity and result in gas cutting of bullets. Greatly increased barrel leading will result if lead bullets are used. None of this can be good for accuracy.

I have many earlier Smith & Wesson revolvers. None have this problem. I have chambered many firearm barrels and have never damaged a forcing cone like this. There can be no good excuse for putting out revolvers with this type of defect. I am hoping others on this Forum will examine their new revolvers and express concern to Smith & Wesson if they find forcing cone defects.

I have Brownell’s forcing cone tools and could use them to attempt my own repair. Jacketed bullets were fired at the Smith & Wesson repair center indicating the burrs are obviously very sturdy and hard to remove. I don’t have confidence the Brownell’s tools will work because of the significant amount of material that would need to be removed. Can Forum members suggest other approaches to repair?

Burrs at these locations are certain to cut grooves down the full length of the bullet bearing surface creating significant leak paths for high pressure gas. These leaks will reduce velocity and result in gas cutting of bullets. Greatly increased barrel leading will result if lead bullets are used. None of this can be good for accuracy.

I have many earlier Smith & Wesson revolvers. None have this problem. I have chambered many firearm barrels and have never damaged a forcing cone like this. There can be no good excuse for putting out revolvers with this type of defect. I am hoping others on this Forum will examine their new revolvers and express concern to Smith & Wesson if they find forcing cone defects.

I have Brownell’s forcing cone tools and could use them to attempt my own repair. Jacketed bullets were fired at the Smith & Wesson repair center indicating the burrs are obviously very sturdy and hard to remove. I don’t have confidence the Brownell’s tools will work because of the significant amount of material that would need to be removed. Can Forum members suggest other approaches to repair?