How does HomeSmith spend his holidays? Working on guns, of course. Duh.

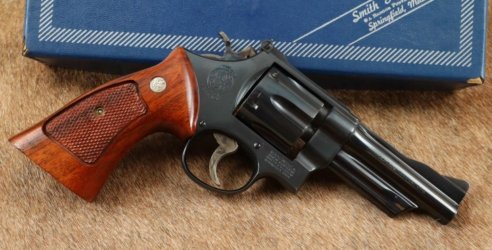

I've been spending so much time on TrainWrecks lately that I've built up a backlog of nice guns that needed attention. Ok - maybe not just "lately". One of the guns that needed help has been in the safe since last year and I'm just now getting around to it. My goal was to work on four .44's in one afternoon: a 624, a 24-3, a 1950 Target, and a Super Blackhawk.

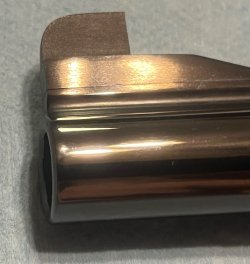

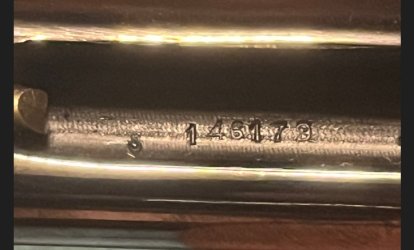

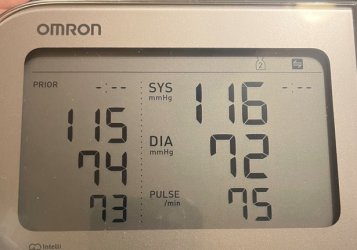

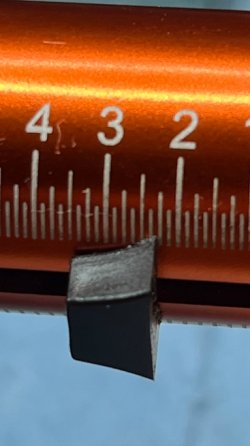

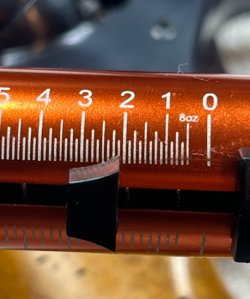

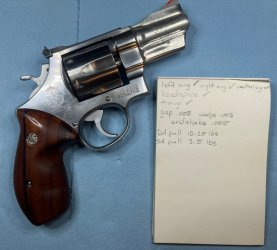

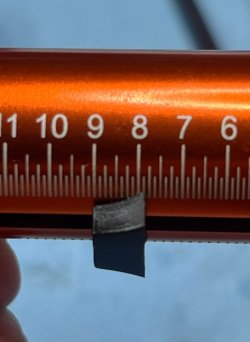

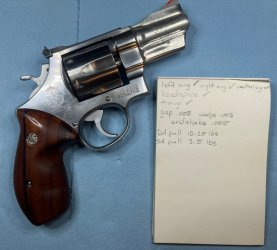

The 624 (code name: Thumper) was up first. As always, we started out with an inspection. The sing in various positions, the rear gauge, and the timing were all good. The cylinder gap was a tight .008" without the wedge and a loose .003" (but not .004") with the wedge, giving us .005" of endshake. The double action pull was 10 1/4 lbs, and the single action pull was 3 1/2 lbs. Nothing scary so far. Other than the sanded-down combat stocks, Thumper seems to be pretty much all original.

Inside, Thumper was very clean and very very dry. Usually when I open up a new gun it's full of goopy stuff that used to be oil. Not this one.

It only took a few minutes to move the insides to the outside and we were ready to begin the fluff and buff.

Judging by the lack of wear marks on the trigger bevel and the general cleanliness of the gun, I'd say that Thumper probably had only a box or two of ammo run through it before arriving at the Shotguncoach Home for Wayward Smiths.

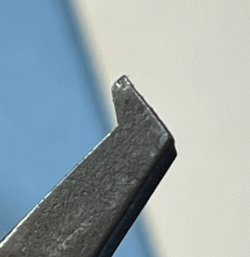

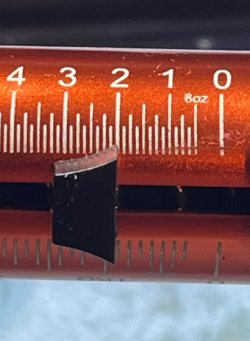

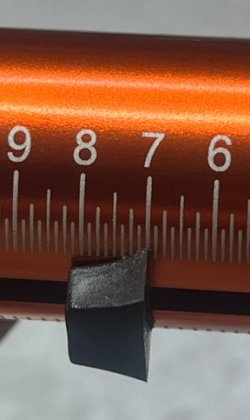

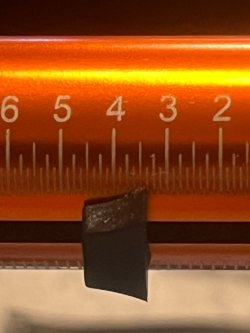

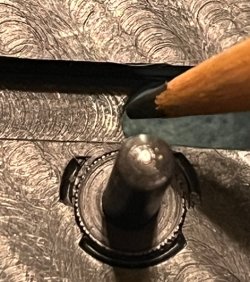

Everything was normal until I picked up the rebound slide unit, removed the spring, and something else fell out. Thumper had an internal trigger stop. I knew that Smith used them but I haven't run into one before. That's pretty spiffy.

The cylinder stop, trigger, and rebound slide were all polished up and reinstalled......and of course I forgot the trigger stop.

I'm very interested in shooting Thumper with the trigger stop side-by-side with a gun that doesn't have the trigger stop so that I can learn just exactly what it does for the shooting experience. I can tell you that the reassembly experience is a PITA because the internal stop prevented me from using the ground-down-screwdriver-inside-the-spring trick to install the rebound slide and I ended up playing possum-up-the-gum-tree with the split end removal tool trying to keep the tool aligned with the spring coils. Several pinched fingers and one launched spring later, it was back together.

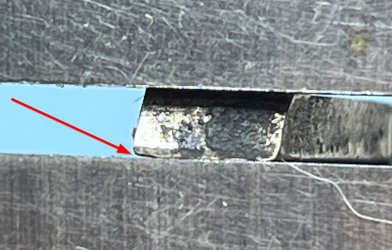

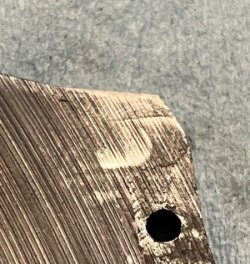

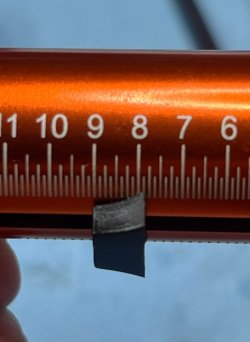

The yoke alignment was spot on, the ejector rod was straight (another clue that Thumper hasn't been shot much), and my good buddy Lance at Triggershims.com supplied a .003" cylinder shim that brought our endshake down to .002". The only other thing that needed to be fixed was to remove a bit of flash from the underside of the thumbpiece that had been rubbing on the frame.

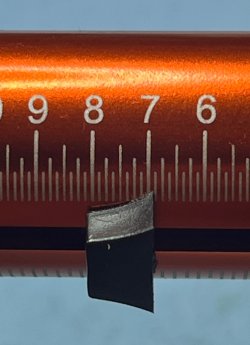

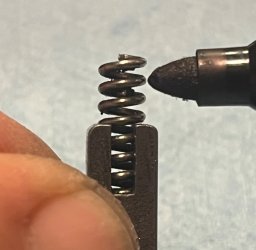

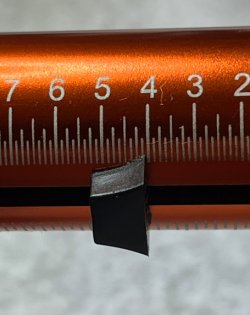

I wanted to try something a little different for the hammer spring. I've been reading about reshaping the spring to affect the hammer tension and trigger pull and this seemed like a good time to learn about that technique. I locked the spring into the big Wilton vise in the garage with only about an inch of spring sticking up and went after it with a 1 lb ball peen hammer. When I had a nice curve in the spring, I did a test fit in the gun, measured the hammer tension, and then went back to the vise, this time positioning the spring in the vise so that an additional inch stuck out. After 4 cycles of this, I ended up with a very curved spring that barely cleared the stock screw. This reshaped spring gave me 56 oz of spring tension (still a bit high) and a double action pull of just barely under 8 pounds. I'm going to try it this way and see how it works, then do some additional experimentation with reducing the radius of the curve near the hooks and increasing the bend to put the spring on the other side of the stock screw. (Thank you to Mr. Protocal_Design for the post about reshaping springs)

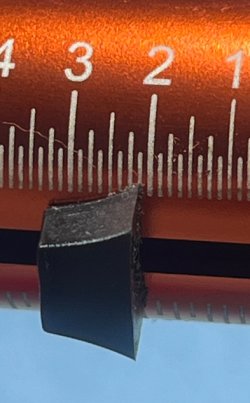

Original spring on the left, reshaped spring for Thumper on the right:

There's room here, but not much, and yes that strain screw is bottomed out - it sticks out of the frame just a bit.

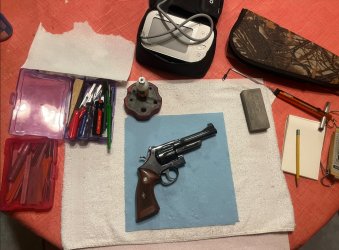

....and we were done with #1:

I've been spending so much time on TrainWrecks lately that I've built up a backlog of nice guns that needed attention. Ok - maybe not just "lately". One of the guns that needed help has been in the safe since last year and I'm just now getting around to it. My goal was to work on four .44's in one afternoon: a 624, a 24-3, a 1950 Target, and a Super Blackhawk.

The 624 (code name: Thumper) was up first. As always, we started out with an inspection. The sing in various positions, the rear gauge, and the timing were all good. The cylinder gap was a tight .008" without the wedge and a loose .003" (but not .004") with the wedge, giving us .005" of endshake. The double action pull was 10 1/4 lbs, and the single action pull was 3 1/2 lbs. Nothing scary so far. Other than the sanded-down combat stocks, Thumper seems to be pretty much all original.

Inside, Thumper was very clean and very very dry. Usually when I open up a new gun it's full of goopy stuff that used to be oil. Not this one.

It only took a few minutes to move the insides to the outside and we were ready to begin the fluff and buff.

Judging by the lack of wear marks on the trigger bevel and the general cleanliness of the gun, I'd say that Thumper probably had only a box or two of ammo run through it before arriving at the Shotguncoach Home for Wayward Smiths.

Everything was normal until I picked up the rebound slide unit, removed the spring, and something else fell out. Thumper had an internal trigger stop. I knew that Smith used them but I haven't run into one before. That's pretty spiffy.

The cylinder stop, trigger, and rebound slide were all polished up and reinstalled......and of course I forgot the trigger stop.

I'm very interested in shooting Thumper with the trigger stop side-by-side with a gun that doesn't have the trigger stop so that I can learn just exactly what it does for the shooting experience. I can tell you that the reassembly experience is a PITA because the internal stop prevented me from using the ground-down-screwdriver-inside-the-spring trick to install the rebound slide and I ended up playing possum-up-the-gum-tree with the split end removal tool trying to keep the tool aligned with the spring coils. Several pinched fingers and one launched spring later, it was back together.

The yoke alignment was spot on, the ejector rod was straight (another clue that Thumper hasn't been shot much), and my good buddy Lance at Triggershims.com supplied a .003" cylinder shim that brought our endshake down to .002". The only other thing that needed to be fixed was to remove a bit of flash from the underside of the thumbpiece that had been rubbing on the frame.

I wanted to try something a little different for the hammer spring. I've been reading about reshaping the spring to affect the hammer tension and trigger pull and this seemed like a good time to learn about that technique. I locked the spring into the big Wilton vise in the garage with only about an inch of spring sticking up and went after it with a 1 lb ball peen hammer. When I had a nice curve in the spring, I did a test fit in the gun, measured the hammer tension, and then went back to the vise, this time positioning the spring in the vise so that an additional inch stuck out. After 4 cycles of this, I ended up with a very curved spring that barely cleared the stock screw. This reshaped spring gave me 56 oz of spring tension (still a bit high) and a double action pull of just barely under 8 pounds. I'm going to try it this way and see how it works, then do some additional experimentation with reducing the radius of the curve near the hooks and increasing the bend to put the spring on the other side of the stock screw. (Thank you to Mr. Protocal_Design for the post about reshaping springs)

Original spring on the left, reshaped spring for Thumper on the right:

There's room here, but not much, and yes that strain screw is bottomed out - it sticks out of the frame just a bit.

....and we were done with #1: