Pictures below.

#1. Picture of tool with specs posted by a generous forum member some time ago.

Thanks again Sir.

#2 and #3 are from our 63-3 and agree with #1.

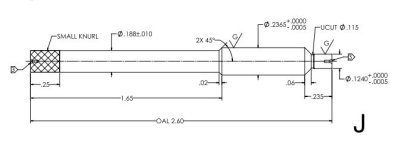

#4 appears to be specs for J frame Center Fire.

Is that correct?

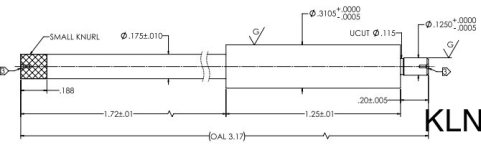

#5 appears to be for KLN frames.

Just wanted to confirm this as the specs of picture #4 was sold when the customer specifically asked for a tool for a 63-3 22LR.

Also, is the .510" length of the yoke barrel pilot short so it can be tapped in that area to make the adjustment, and no need for it to be any longer?

Makes sense to me.

Cylinder End Shake.

Would you make it .001" or .002"?

No yoke movement issues.

The BC gap will be about .011" maybe .012" which is Smith's current Max spec. Will deal with that after test firing if needed.

Thanks again all.

RT

#1. Picture of tool with specs posted by a generous forum member some time ago.

Thanks again Sir.

#2 and #3 are from our 63-3 and agree with #1.

#4 appears to be specs for J frame Center Fire.

Is that correct?

#5 appears to be for KLN frames.

Just wanted to confirm this as the specs of picture #4 was sold when the customer specifically asked for a tool for a 63-3 22LR.

Also, is the .510" length of the yoke barrel pilot short so it can be tapped in that area to make the adjustment, and no need for it to be any longer?

Makes sense to me.

Cylinder End Shake.

Would you make it .001" or .002"?

No yoke movement issues.

The BC gap will be about .011" maybe .012" which is Smith's current Max spec. Will deal with that after test firing if needed.

Thanks again all.

RT

Attachments

-

912040EF-BC26-4722-B6B9-5CC5DC5EEB45.jpg180.1 KB · Views: 101

912040EF-BC26-4722-B6B9-5CC5DC5EEB45.jpg180.1 KB · Views: 101 -

33BC7438-AD60-4893-96A5-D96A0D703E15.jpg62.2 KB · Views: 80

33BC7438-AD60-4893-96A5-D96A0D703E15.jpg62.2 KB · Views: 80 -

3B406D47-B935-4F6C-98F4-356BF82104E5.jpg55.1 KB · Views: 78

3B406D47-B935-4F6C-98F4-356BF82104E5.jpg55.1 KB · Views: 78 -

F39639A8-7E1C-4A64-8BE0-09E7EF07C944.jpeg23.1 KB · Views: 81

F39639A8-7E1C-4A64-8BE0-09E7EF07C944.jpeg23.1 KB · Views: 81 -

4EEE87CB-3298-4EFB-AF75-7728E2DA907E.jpeg24.6 KB · Views: 54

4EEE87CB-3298-4EFB-AF75-7728E2DA907E.jpeg24.6 KB · Views: 54