As it was explained to me:

Inside the revolver, on the interior LEFT frame is a stud, integral to the frame, the the hammer pivots on. The other end of this stud fits into a hole in the sideplate.

In the NYPD guns, the Department maintained that this hole was oversized and that the mainspring exerted enough force to cause the stud to bend slightly, taking the hammers path out of true. The Department further maintained that if the sideplate hole did not have excessive play, it would support the end of the stud properly and this wold not be an issue.

Why did this not happen with the regular production guns? Mainly because they were for non-LE sales and were SA/DA.

Again, as it was explained to me: By removing the hammer spur, the overall weight/mass of the hammer was decreased. The decrease in mass changed the amount of force with which the firing pin would hit the hammer. It wasn't an issue during testing, but it was determined that the amount of force the lightened hammer generated was close to, but not entirely, within the specs for consistently reliable ignition.

Since the weight of the hammer could not be increased, the answer was to have the weight of the mainspring increased so as to have the hammer strike with more force. This heavier mainspring, however, put more pressure on the hammer, thus more pressure on the hammer stud pin, and that caused the pin to flex just enough that, if the hole in the sideplate were oversized, would allow the stud to shift out of true and bind the hammer.

I can't say this is what the actual issue was. I'm merely relating what the cadre at the Firearms Unit related to me. S&W, of course, according to their lawyers, interpreted the situation differently. I'm only repeating what the Department told me and what their internal records reflected. I am sure that the factory version is somewhat different.

The factory did recognize that financial discretion was the better part of reputational valor and decided to eat the cost of replacing the guns.

Best,

RM Vivas

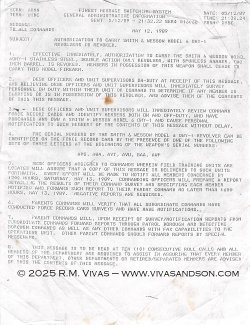

) on the NY-1 family of Smith & Wessons and came across this document in my archive. It is the fax notice sent to all commands on 12MAY89 ordering the immediate cessation of use of the Model 60 NY-1 by all MOS.

) on the NY-1 family of Smith & Wessons and came across this document in my archive. It is the fax notice sent to all commands on 12MAY89 ordering the immediate cessation of use of the Model 60 NY-1 by all MOS.