I just found this thread, and want to encourage you to continue posting your trials and tribulations with this somewhat unusual cartridge.

My thoughts on the splitting nickel cases - I would continue shooting them until gone.

I shall follow your advice. And have fun doing it!

Today I went to the range and burned through another hundred rounds. As expected I experienced fantastic accuracy, lots of flash and noise, and tremendous satisfaction, while having to tap many of the split cases out of the cylinder with a pencil and small wood mallet.

I did have a new experience today. I had about 8-9 rounds that failed to fire completely, and another 2-3 hang-fires, where the round fired a half-second or so after the primer was struck. All were from one particular box. The second box was loaded to the same specs with the same components a week after the first, and functioned flawlessly, as have all the previous rounds I’ve fired.

Given that my process is to tumble, then form (or resize, in the situation of previously formed then fired cases) and then run the cases through the dishwasher to remove the case lube, then dry in the sun before loading, could it be that I was a bit impatient and loaded a box with cases that had not fully dried, and some primers got soaked and failed to fire? Or could some tumbling media have gone unnoticed in the bottom of the previously fired cases, and blocked the path from the primer to the powder? Your guess is as good as mine (and for many of you, probably substantially better) but rest assured I will take great care to ensure that all cases are completely free of all moisture and potential obstructions before loading any more rounds.

The cases suffered varying degrees of trauma during firing today, as in previous days, and all were unceremoniously dumped in the recycling bin after firing. I have 300 new brass (not nickel) cases ready to load, with 200 more enroute which will be formed right away, for a total of 500. I will probably start off loading just a box of 50 to make sure my load of 22.0 gr of WW-296 will allow for reliable functioning with no problems of sticky case extraction, setback etc.

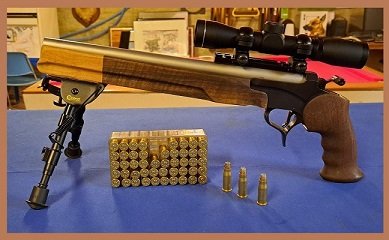

Oh, I did notice one odd thing. I found that a couple of bullets had their jackets shaved and bits of jacket were deposited on the bench as the bullet made its way from the gun to the target. (See photo). What would account for this?