I purchased a S&W Model 14 a few months back from Gunbroker, and finally got around to cleaning it so I can start shooting it. Came apart fine, definitely needed a cleaning, and started to go back together.

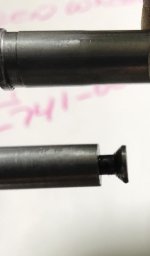

Now I've got one concern - the small screw that holds the yoke in place went in fine, and I went to "snug it up", but it "felt funny". I'm used to the way this feels on my other S&W revolvers. So I just stopped, and left it as-is.

Is this a "standard part" that I can buy a new one, and replace it, or is it custom fitted to the gun? I don't want to risk having it break, at which point I've got a much bigger issue to deal with.

Maybe it's fine, and it's just my imagination, but if I can buy a new part, better to be safe than sorry. I can take it out and photograph it, if that would be helpful.

(What felt strange, is when I put in this screw in my other guns, it gets tighter and tighter, until I stop. This screw felt perfect as it was starting to tighten, but then it suddenly felt slightly "easier", and I instantly stopped. Everything may be normal - maybe the parts just shifted slightly, but if I can replace it, I'd like to do so.)

I can see the "yoke", part #25 on this page, but it's not clear where the screw is that holds the yoke in place:

http://www.vivasandson.com/m14.pdf

Now I've got one concern - the small screw that holds the yoke in place went in fine, and I went to "snug it up", but it "felt funny". I'm used to the way this feels on my other S&W revolvers. So I just stopped, and left it as-is.

Is this a "standard part" that I can buy a new one, and replace it, or is it custom fitted to the gun? I don't want to risk having it break, at which point I've got a much bigger issue to deal with.

Maybe it's fine, and it's just my imagination, but if I can buy a new part, better to be safe than sorry. I can take it out and photograph it, if that would be helpful.

(What felt strange, is when I put in this screw in my other guns, it gets tighter and tighter, until I stop. This screw felt perfect as it was starting to tighten, but then it suddenly felt slightly "easier", and I instantly stopped. Everything may be normal - maybe the parts just shifted slightly, but if I can replace it, I'd like to do so.)

I can see the "yoke", part #25 on this page, but it's not clear where the screw is that holds the yoke in place:

http://www.vivasandson.com/m14.pdf

Last edited: