It's my understanding that 1911 and A1 slides were not hardened until after WW2. At least the ones produced for the military.

I could be wrong about that but it's the reason I don't shoot my RR with a Colt slide that is WW2 vintage. If I could get some good verification that the slide was hardened I'd probably shoot it some. I have another 1911 that gets a regular workout.

A collector over on another forum insisted that they were not hardened but I don't know the facts.

Two thoughts.

First, I can't speak directly to the A1 slides, as it may have only applied to the Colt commercial slides. What changed for Colt was the availability of tungsten carbide cutting tool steel which Colt began using in 1924.

The high speed tool steel used prior to that could not mill a hardened slide to its final dimension, which is why the slides could not be heat treated as the heat treat process warped the slide, and in particular the rails on the slide.

The government might not have cared on the A12 and might not have specified the front portion of the slide be hardened.

Second, there are also three different things referenced in terms of hardening.

The biggest issue with the 1911 slide was that the slide could crack about 1/3rd of the way back where the recoil spring cover stops and steps to the slide rail, creating a sharp corner / stress riser. My understanding is this is the portion of the slide that was hardened on Colt commercial pistols beginning in 1924.

My understanding is that all 1911A1s also had this area hardened, but I could be wrong. It's possible that pre war A1 slides were hardened in the front third of the slide during a post war arsenal refurbishment. Generally speaking, "new" 1911A1s showed some discoloration in this area from the heat treatment process, much like heel dipped Garand receivers( where the rear of the receiver was hardened by dipping the rear half in molten lead).

However, after refinishing that discoloration on 1911 slides is much less visible.

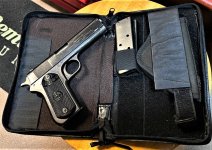

Slide stop notches were spot hardened beginning in 1942, to prevent the slide stop notch from peening. These are Star BM pistols, not 1911s, but when they started having issues with slide stops cracking, they started drilling the corner to create a larger radius and then spot heat treated that area. On the lower pistol it's very evident. On the one above, it's not.

Fully hardened slides were experimented with during WWII, and if I remember correctly Remington-Rand used induction hardening for this, with questionable results. However, fully hardened slides didn't appear on the Colt Commerical pistols until 1947.

The government didn't buy many 1911A1 after WWII, but IIrC did buy a batch in 1950 gearing up for the Korean conflict and my understanding is that these were fully hardened, along with a handful that were fully hardened late in the war as various manufacturers experimented with it.

That would mean that very few A1 slides were ever "fully hardened".