AJ

US Veteran

I am a bit old school and use media tumblers. Started with a Lyman and used it for years, Came into possession of a Midway Model 1292 Tumbler and have used it for several years. For some reason I decided to look it up on line and found out that they were recalled in 1998, for failures and fires. No problems with this one in the last 10 years, but decided to call their Customer Service. Was told to send it back and they will send me a new tumbler. Was surprised to say the least, considering the recall is 25 years old.

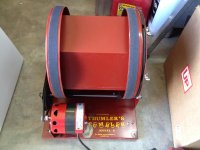

Right now I am using a Thumbler's Tumbler Ultra-Vibe 18. While it does get the job done it is more noisy than the Midway. Also have a Lyman Cyclone Tumbler and it is even more noisy.

So my question is who make the least noisy media tumblers. Don't want to do pins or liquids, just media. TIA

Right now I am using a Thumbler's Tumbler Ultra-Vibe 18. While it does get the job done it is more noisy than the Midway. Also have a Lyman Cyclone Tumbler and it is even more noisy.

So my question is who make the least noisy media tumblers. Don't want to do pins or liquids, just media. TIA