Doug M.

Member

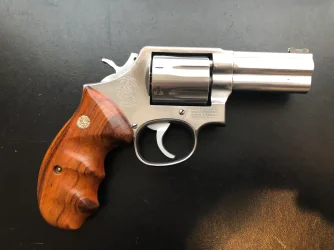

I loathe full lug barrels. There is not a single thing about them I like. This man has a goal in mind to make the revolver be what he desires, and seems to know what the fiscal impact might be. The collector perspective on this project is completely irrelevant. Get off your high horse and be helpful, or skip the string.