I have used Hoppe's #9 since 1978.

About 3 months ago I was watching a YT video of a guy using Hoppe's, then using Bore Tech Inc's Cu+2 Copper Remover on his bore of an AR15. I was very surprised at how much copper comes out onto the patches.

I have now switched to Cu+2 Copper Remover on all parts because it cleans so well on carbon and ammo residue, and especially copper, out of the bore. I run a wet cloth patch through bore and let set for about 5 or 10 minutes, then do it again until there is very little to no "green" copper coming out on the patches. It has no ammonia.

https://a.co/d/02g7Nf9

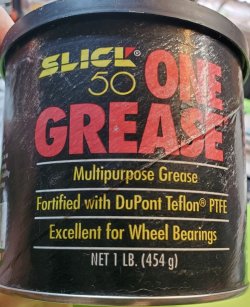

Recently I was watching a YT video on lubricating a firearm with grease. I have never used a "grease" on any of my guns. I live in the Arizona desert where the average yearly temperature is 73.7d F, and the average July temperature is 106d F. I decided to try some grease. I took some synthetic Slick 50 wheel bearing grease, with Teflon, and put it in a 5.0 ml syringe. I field stripped and, with a q-tip, put a very thin layer on key metal-on-metal shiny areas, slide rails and guide rod spring assembly, on my freshly cleaned and lubed BG2 and P365 Micro.

I was very surprised at the smoothness of the "feel" when racking the slide, but also surprised at how the grease reduced the actual sound of racking the slide. I "greased" 3 other pistols.

I will be at the range on Saturday with 9 other hole-punching deplorables, so I will see how my "grease guns" work. I'll bring up the topic of cleaning, oils, grease and lubrication during our post hole-punching fun at lunch.