You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How did I do? (.38 Safety Hammerless)

- Thread starter 9245

- Start date

"let me know"

spoken like a true fellow collector!I like the long barrels. Can you tell us what that stamp is on the barrel lug? Or am I imagining something there?

If you can't find a side plate nut let me know. I have a few in my parts bin.

Murph

Boulder350

Member

Here is a 6" barreled 38 Safety Hammerless. Its about 5 1/8" from the safety at the back of the grip to the end of the hinge. From the end of the hinge to the end the barrel is about the same, 5 1/8".

On the original posters gun these measurements are not equal making it a 5" barrel.

I did a search on Ebay for parts. I searched "Smith Wesson 38 Lemon Squeezer Sidelplate screw". Voila. There may be less expensive options out there, like the offers of parts from other forum members. Numrich is out of stock, their's were $8.50 each plus shipping.

On the original posters gun these measurements are not equal making it a 5" barrel.

I did a search on Ebay for parts. I searched "Smith Wesson 38 Lemon Squeezer Sidelplate screw". Voila. There may be less expensive options out there, like the offers of parts from other forum members. Numrich is out of stock, their's were $8.50 each plus shipping.

Attachments

Last edited:

typos

In an effort to judge barrel length I took a piece of paper and marked the length of the cylinder from my monitor and then used that distance from the cylinder face to the muzzle to see how many to the muzzle.

There were more on the 6" gun shown by Boulder350 than on the photo of the op's gun.

A very rudimentary process but even if the photos shown are not the same size, the length of the cylinder compared to the length of the barrel should be proportional in each photo.

OP, once you have the parts needed and you give the old girl a bath to un-gunk her innards, we will need photos of the before and after.

The offer by Murph to look in his parts bin for a replacement speaks highly of this collector community. I love seeing roughed up S&W's brought back to function. Does not have to end up as a safe queen but to have it returned to a shooter from non working status always brings a smile to my face.

Again, we sitting and watching will need photos.

In an effort to judge barrel length I took a piece of paper and marked the length of the cylinder from my monitor and then used that distance from the cylinder face to the muzzle to see how many to the muzzle.

There were more on the 6" gun shown by Boulder350 than on the photo of the op's gun.

A very rudimentary process but even if the photos shown are not the same size, the length of the cylinder compared to the length of the barrel should be proportional in each photo.

OP, once you have the parts needed and you give the old girl a bath to un-gunk her innards, we will need photos of the before and after.

The offer by Murph to look in his parts bin for a replacement speaks highly of this collector community. I love seeing roughed up S&W's brought back to function. Does not have to end up as a safe queen but to have it returned to a shooter from non working status always brings a smile to my face.

Again, we sitting and watching will need photos.

Last edited:

Boulder350

Member

Another thing to look for is a taller front sight on a 6" or longer barrel on the 32 and 38 top breaks. Not all the time will the longer barrels wear them, but the majority do. Here is a picture of front sights on a 32 S&W with 6" barrels. Both have a taller front sight than normal in 2 different configurations. The same style of taller front sights are applied to the 38.

Compare the front sights on my 38 Safety Hammerless with the gun from 9245.

Compare the front sights on my 38 Safety Hammerless with the gun from 9245.

Attachments

Last edited:

In an effort to judge barrel length I took a piece of paper and marked the length of the cylinder from my monitor and then used that distance from the cylinder face to the muzzle to see how many to the muzzle.

There were more on the 6" gun shown by Boulder350 than on the photo of the op's gun.

A very rudimentary process but even if the photos shown are not the same size, the length of the cylinder compared to the length of the barrel should be proportional in each photo.

OP, once you have the parts needed and you give the old girl a bath to un-gunk her innards, we will need photos of the before and after.

The offer by Murph to look in his parts bin for a replacement speaks highly of this collector community. I love seeing roughed up S&W's brought back to function. Does not have to end up as a safe queen but to have it returned to a shooter from non working status always brings a smile to my face.

Again, we sitting and watching will need photos.

I will indeed post pictures and measurements when I have it in hand, the pictures I have now are just from the auction. The seller wants payment by postal money order so it will take a few days before he even ships. And I agree, I love bringing old guns back to life, the last one I brought back was an 1870s hammered SXS that was an absolute mess (technically I still have work to do on that one, it needs a new extractor/ejector but I need the tools to extract the old broken "tail" and fab a new one or repair that one somehow, but the rest of the work is done).

I like the long barrels. Can you tell us what that stamp is on the barrel lug? Or am I imagining something there?

If you can't find a side plate nut let me know. I have a few in my parts bin.

Murph

I would greatly appreciate that if I can't find one! And so far I am coming up goose eggs.

As for the stamp I have no idea, I don't see it myself, but once I get it in hand I will check for you.

Last edited:

- Joined

- Dec 1, 2022

- Messages

- 883

- Reaction score

- 1,425

Hi There,

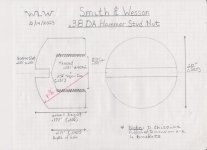

I made my measurements and made a drawing of the part.

Unfortunately, the thread used in the nut is a non-standard

size but is very close to #5 x 40 tpi. A #5 screw has a major

diameter of .125" and the threads on the Hammer Stud has a

major diameter of .131". This would mean I would have to

make a custom tap (or two) to cut the threads and this would

be time consuming and therefore expensive.

There is some good news, After consulting David Chicoine's

book: Gunsmithing the Guns of the Old West 2nd Ed.,

He implies the Hammer Stud Nut for the .38 is the same as

the one for the .32. You could search flea-Bay for "smith

wesson 32 side plate nut" and find one.

Sorry I cannot be more help.

Cheers,

Webb

I made my measurements and made a drawing of the part.

Unfortunately, the thread used in the nut is a non-standard

size but is very close to #5 x 40 tpi. A #5 screw has a major

diameter of .125" and the threads on the Hammer Stud has a

major diameter of .131". This would mean I would have to

make a custom tap (or two) to cut the threads and this would

be time consuming and therefore expensive.

There is some good news, After consulting David Chicoine's

book: Gunsmithing the Guns of the Old West 2nd Ed.,

He implies the Hammer Stud Nut for the .38 is the same as

the one for the .32. You could search flea-Bay for "smith

wesson 32 side plate nut" and find one.

Sorry I cannot be more help.

Cheers,

Webb

Attachments

- Joined

- Dec 1, 2022

- Messages

- 883

- Reaction score

- 1,425

Hi There,

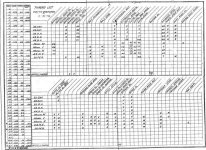

I've seen that chart before. I just forgot about it. What I will

say is that my measurements (and those of David Chicoine)

differ slightly. Using a nut that has a major diameter .004"

larger will work okay but will be loose fitting on the stud's

threads.

I have read that S&W used a 60° Vee form thread and using

the USS system of threads, a 40 tpi thread is .016238" deep

(Depth = Pitch x .64952). This assumes there is a small flat

section at the root and the crest of the threads. This "flat" is

(or used to be) 1/8th of the Pitch or in this example, .003125".

If the threads are a "sharp" 60° Vee, then the thread depth is

a little more (Depth = Pitch x .866025) and would be .021651"

(or .0054" deeper).

I only point this out because the 60° thread profile can be proble-

matic when some of the data is not known and the machining

of test pieces are needed to test the thread size fit.

Cheers!

Webb

Post Script:

I've been thinking about this difference in major thread diameter

and I think S&W were trying the make threading easier for

the gunsmiths. You see, a #6 screw is .138" in diameter and

#6 x 40 is a readily available tap. This would only be .003"

bigger and would work (although it would be a little loose on

its threads). Seeing that this "nut" fits into a counter-bored

hole in the sideplate, the nut would not tend to move once

the nut was installed and tightened.

I've seen that chart before. I just forgot about it. What I will

say is that my measurements (and those of David Chicoine)

differ slightly. Using a nut that has a major diameter .004"

larger will work okay but will be loose fitting on the stud's

threads.

I have read that S&W used a 60° Vee form thread and using

the USS system of threads, a 40 tpi thread is .016238" deep

(Depth = Pitch x .64952). This assumes there is a small flat

section at the root and the crest of the threads. This "flat" is

(or used to be) 1/8th of the Pitch or in this example, .003125".

If the threads are a "sharp" 60° Vee, then the thread depth is

a little more (Depth = Pitch x .866025) and would be .021651"

(or .0054" deeper).

I only point this out because the 60° thread profile can be proble-

matic when some of the data is not known and the machining

of test pieces are needed to test the thread size fit.

Cheers!

Webb

Post Script:

I've been thinking about this difference in major thread diameter

and I think S&W were trying the make threading easier for

the gunsmiths. You see, a #6 screw is .138" in diameter and

#6 x 40 is a readily available tap. This would only be .003"

bigger and would work (although it would be a little loose on

its threads). Seeing that this "nut" fits into a counter-bored

hole in the sideplate, the nut would not tend to move once

the nut was installed and tightened.

Last edited:

Hi There,

I made my measurements and made a drawing of the part.

Unfortunately, the thread used in the nut is a non-standard

size but is very close to #5 x 40 tpi. A #5 screw has a major

diameter of .125" and the threads on the Hammer Stud has a

major diameter of .131". This would mean I would have to

make a custom tap (or two) to cut the threads and this would

be time consuming and therefore expensive.

There is some good news, After consulting David Chicoine's

book: Gunsmithing the Guns of the Old West 2nd Ed.,

He implies the Hammer Stud Nut for the .38 is the same as

the one for the .32. You could search flea-Bay for "smith

wesson 32 side plate nut" and find one.

Sorry I cannot be more help.

Cheers,

Webb

Thanks for checking for me, I appreciate it.

I just ran a check for the .32 on eBay and am still coming up blank, I saw one bundled with the side plate but I don't need the side plate and really don't like the idea of paying for it unless I have absolutely no choice.

spoken like a true fellow collector!

^^^Amen^^^

FWIW your first picture shows the front of the cylinder at 4-1/4" and the muzzle at around 10-1/4".Here is a 6" barreled 38 Safety Hammerless. Its about 5 1/8" from the safety at the back of the grip to the end of the hinge. From the end of the hinge to the end the barrel is about the same, 5 1/8".

On the original posters gun these measurements are not equal making it a 5" barrel.

I did a search on Ebay for parts. I searched "Smith Wesson 38 Lemon Squeezer Sidelplate screw". Voila. There may be less expensive options out there, like the offers of parts from other forum members. Numrich is out of stock, their's were $8.50 each plus shipping.

So it seems pretty clear that you have a top-break 38 with a 6" barrel.

Please forgive me if I am being Captain Obvious...

Last edited:

I got it!

Just arrived. I think the root of the problem is that someone was screwing with it and put it back together wrong. The grip safety is frozen, the trigger is frozen, and the latch is frozen. I had to remove the hinge pin to get it open. It looks like some dumb monkey took a saw to the breech face at some point in history for unknown reasons (see pictures), maybe the same person who screwed it up. Once I got it to open the extractor seemed to work and the trigger started moving again and the trigger spring seems to be working fine, as does the hand and cylinder stop. The barrel still has clear rifling, there might be some light pitting but I'm not sure yet, I will have to clean it and see.

As I thought the hammer nut is missing and the one grip is chipped. The nickel is very degraded but still present, maybe 70%. The barrel is 5 inches, not 6.

I think the root of the problem is that someone took it apart and did not know how to put it back together.

On that note, where can I find detail strip and reassembly instructions/videos?

I saw no marking at the hinge that was asked about before.

Just arrived. I think the root of the problem is that someone was screwing with it and put it back together wrong. The grip safety is frozen, the trigger is frozen, and the latch is frozen. I had to remove the hinge pin to get it open. It looks like some dumb monkey took a saw to the breech face at some point in history for unknown reasons (see pictures), maybe the same person who screwed it up. Once I got it to open the extractor seemed to work and the trigger started moving again and the trigger spring seems to be working fine, as does the hand and cylinder stop. The barrel still has clear rifling, there might be some light pitting but I'm not sure yet, I will have to clean it and see.

As I thought the hammer nut is missing and the one grip is chipped. The nickel is very degraded but still present, maybe 70%. The barrel is 5 inches, not 6.

I think the root of the problem is that someone took it apart and did not know how to put it back together.

On that note, where can I find detail strip and reassembly instructions/videos?

I saw no marking at the hinge that was asked about before.

Last edited:

I discovered that the hammer was not engaging with the trigger, but tapping the back of the hammer with a punch knocked it back in to position, which also completely freed up the latch, allowing normal operation, however pulling the trigger once (which turned the cylinder and operated the hammer as expected) knocked it back out of position again as you said. As for the cause? Either the hammer is wobbling slightly due to the missing stud nut, and/or the safety is still gunking things up, can't say for certain yet.

I just sent it through the ultra sonic cleaner with distilled water and dish soap for a full hour, with heat, a horrendous slimy rusty black mess was dislodged from the revolver, after wiping it all off I put it in K1 Kerosene to soak, which is where it will stay for a few days at least, after it comes out I will see if the pins are a bit more cooperative and if the grip safety unsticks itself.

Similar threads

- Replies

- 1

- Views

- 236

- Replies

- 15

- Views

- 337

- Replies

- 1

- Views

- 348