I have a new Ruger MK4 22 Target model that has a factory stripped screw on the top of the barrel. It is an Allen hex head screw filling the mounting hole used for a sight rail. Actually there are 3 blanked screw holes. I noticed that one of the screws was vibrating outwards when firing the gun, so when I got home I pulled the screw, and put a dab of blue locktite on it. Then I decided to check the other 2 screws. One came out a bit hard, but it was not cross threaded. The last one, has a stripped Allen hex head. I have no idea of the condition of the threads.

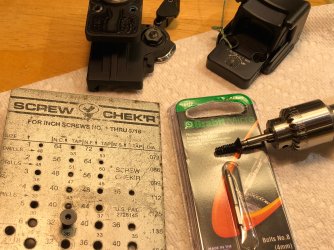

So my question is, how to remove the screw. I do not have mini extractors, nor do I have a drill press for enlarging the hole if need be. This is like a size 4 or 5 screw.

I thought about epoxying an Allen key into the stripped hole to turn it

You know, in the 70's I bought a Ruger 77 and it had a part recall, in the mid 80's I bought a stainless super blackhawk, and under recoil the ejector, shroud and spring flew off the gun.

Now this issue with a 6 cent screw. And this is not the only issue on this gun. It was missing a part #39 screw that is part of the bolt release system. How did they test fire this unit?

So my question is, how to remove the screw. I do not have mini extractors, nor do I have a drill press for enlarging the hole if need be. This is like a size 4 or 5 screw.

I thought about epoxying an Allen key into the stripped hole to turn it

You know, in the 70's I bought a Ruger 77 and it had a part recall, in the mid 80's I bought a stainless super blackhawk, and under recoil the ejector, shroud and spring flew off the gun.

Now this issue with a 6 cent screw. And this is not the only issue on this gun. It was missing a part #39 screw that is part of the bolt release system. How did they test fire this unit?