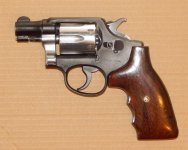

I'm helping a friend with a rough condition New Zealand marked 1942 S&W M&P that started life as a 5 inch .38 S&W. Besides the probable reaming to .38 Special, the cylinder has damage that makes it unusable. On top of the good lock work with a smooth DA/SA, what makes the thing worthy of further effort is the honest .38 Special 2 inch barrel that was installed at some time in the past.

A newer .38 Special cylinder dropped in with good hand to ratchet fit & carry up. I'm surprised too. That's not supposed to happen.

The next problem is replacing the severely worn cylinder stop. 5-screw stops I've seen listed for sale appear to be in dubious condition. SO – can a modern cylinder stop - with the hole for a spring right where the plunger in a 5-screw stop must bear - be adapted to a 5-screw frame?

I can see a couple of ways to go about it, but what is best and/or easiest?

The easiest solution would seem be to Dremel out a deeper recess in the frame for the spring. Is there enough metal in the frame – following the hole for the 5-screw plunger and spring – for that to work?

It's already a Frankengun, so anything done to make it safely functional can only be an improvement.

===========================

Edit to save scrolling to the end: yes, it works to fill the hole in a new cylinder stop and then modify - a bunch - the profile to match the 5-screw cylinder stop.

..

A newer .38 Special cylinder dropped in with good hand to ratchet fit & carry up. I'm surprised too. That's not supposed to happen.

The next problem is replacing the severely worn cylinder stop. 5-screw stops I've seen listed for sale appear to be in dubious condition. SO – can a modern cylinder stop - with the hole for a spring right where the plunger in a 5-screw stop must bear - be adapted to a 5-screw frame?

I can see a couple of ways to go about it, but what is best and/or easiest?

The easiest solution would seem be to Dremel out a deeper recess in the frame for the spring. Is there enough metal in the frame – following the hole for the 5-screw plunger and spring – for that to work?

It's already a Frankengun, so anything done to make it safely functional can only be an improvement.

===========================

Edit to save scrolling to the end: yes, it works to fill the hole in a new cylinder stop and then modify - a bunch - the profile to match the 5-screw cylinder stop.

..

Attachments

Last edited: